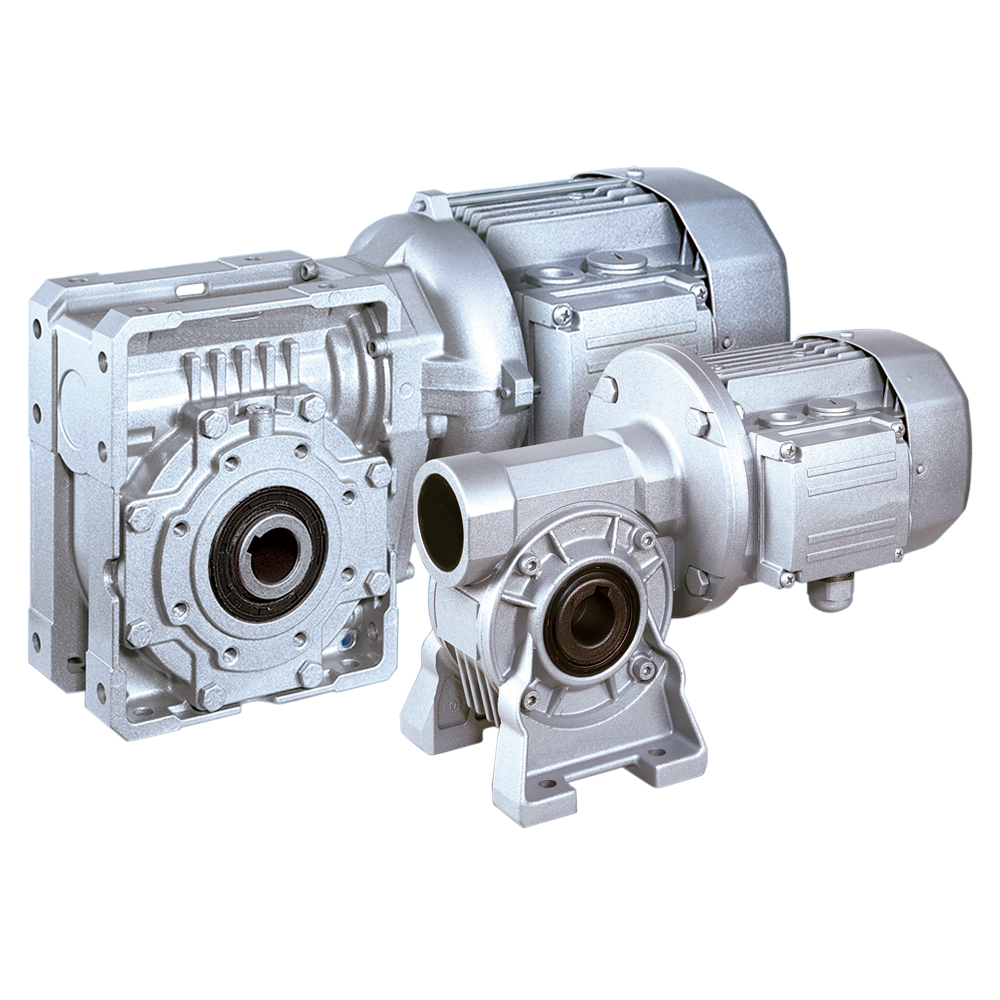

VF/W series

Worm gear reducers

The worm gearboxes from the VF and W series can be easily integrated in most machines and installations. Thanks to their compact design high torque, high gear ratio applications in limited spaces are possible. Due to the design principle, the higher the gear ratio, the lower the efficiency. In many applications it effectively prevents the need for a more expensive brake motor.

Look at the column with reducer types

| Type

|

Torque [Nm]

|

| VF 27

|

13

|

| VF 30

|

24

|

| VF 44

|

55

|

| VF 49

|

88

|

| W 63

|

190

|

| W 75

|

320

|

| W 86

|

440

|

| W 110

|

830

|

| VF 130

|

1.500

|

| VF 150

|

2.000

|

| VF 185

|

3.600

|

| VF 210

|

5.000

|

| VF 250

|

7.100

|

Torque: 13 - 7.100 Nm

Output power: (@ 1400 rpm): 0,04 – 75 kW

Gear ratios: 7 - 10.000

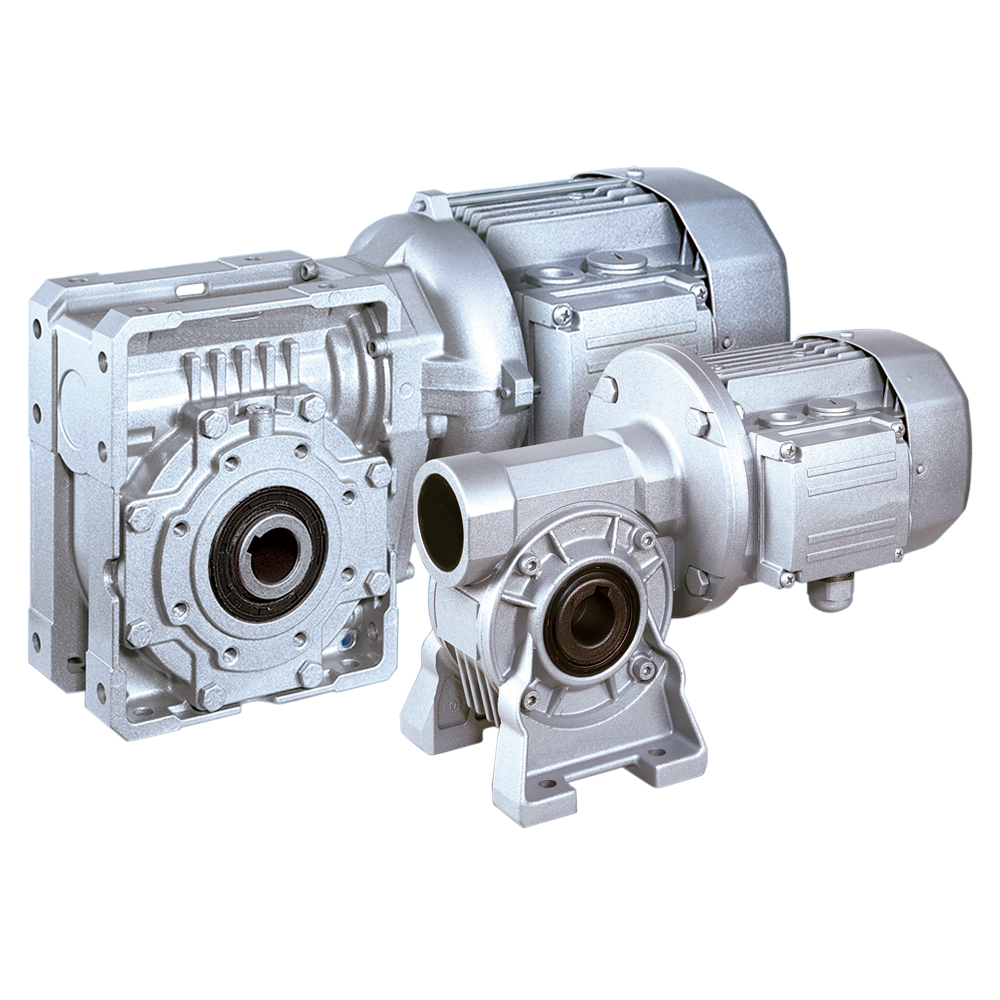

VF-EP/W-EP series

Worm gear reducers with increased protection

The worm gearboxes of the VF and W series are also available with increased protection for use in aggressive environments. This EP (Enhanced Protection) version was especially developed for the food and beverage and chemical and pharmaceutical industries. This high corrosion resistance version is also used in maritime and mining applications.

Look at the column with reducer types

| Type

|

Torque [Nm]

|

| VF 44

|

55

|

| VF 49

|

88

|

| W 63

|

190

|

| W 75

|

320

|

| W 86

|

440

|

Torque: 55 - 440 Nm